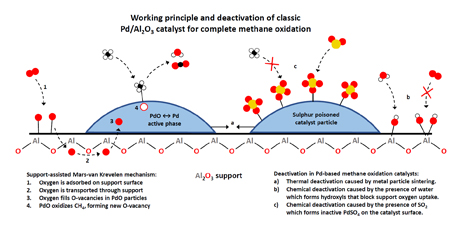

Being 28 to 87 times more potent a greenhouse gas than CO2, the increasing amount of unburned methane from natural gas-fired engines poses a severe threat to humanity. Fortunately, it can potentially be removed from the exhaust through catalysis. Methane oxidation is kinetically hindered by the strong C-H bond (435 kJ/mol), and therefore requires an efficient catalyst that can lower the activation energy and allow the reaction to occur at reasonable temperatures. It has been shown that supported metallic Palladium (Pd) nanoparticles are by far the most active. They do, however, undergo three severe and fast modes of deactivation, which are the primary challenges to overcome:

1. Thermal deactivation caused by metal particle sintering.

2. Chemical deactivation caused by the presence of water.

3. Chemical deactivation caused by the presence of SO2 which can form PdSO4 or react with the support material.

Hydrophobic zeolites have shown great promise in overcoming both thermal sintering and water deactivation, while various metal oxides have been used for lowering SO2 deactivation. This project combines these two features in an attempt to make a catalyst that is both thermally stably as well as resilient towards deactivation by water and SO2.

Description of suggested student project:

The project offered is supervised by professor Susanne Mossin and co-supervised by industrial PhD Rasmus Lykke Mortensen. It revolves around complete methane oxidation, the process by which unburned methane is removed from the exhaust of natural gas-fired engines. You will have the freedom to choose the direction of your own project, but we have multiple ideas for promising materials. This includes combinations of zeolites, precious metals, spinels, redox-active metal oxides among others. The project is circular in nature, meaning that you will synthesize materials, then test them, perform characterization, analyze the results, and then start over again from materials synthesis using the obtained knowledge from the previous cycle.

The project can/will have to be done in collaboration with Umicore Denmark ApS depending on the eventual project description that you take part in defining with the supervision team. Umicore is a global leader in sustainable technology and provides exhaust treatment solutions to a range of industries.

We expect you to be highly motivated and have a strong background in both theoretical and experimental inorganic chemistry, as well as some understanding of reaction kinetics and catalysis.